Free Classifieds at UKAdsList.com - View Item Content by ID 8580840

UKAdsList > Internet Services > Other Internet Services > Item ID 8580840

Item ID 8580840 in Category: Internet Services - Other Internet Services

Cannot view this item. It could be pending, expired or deleted.

Below item is randomly selected from the same category and may have similar content.

Robotic Integration and Automation Solutions, Global Market Size Forecast, Top 29 Players Rank and M | |

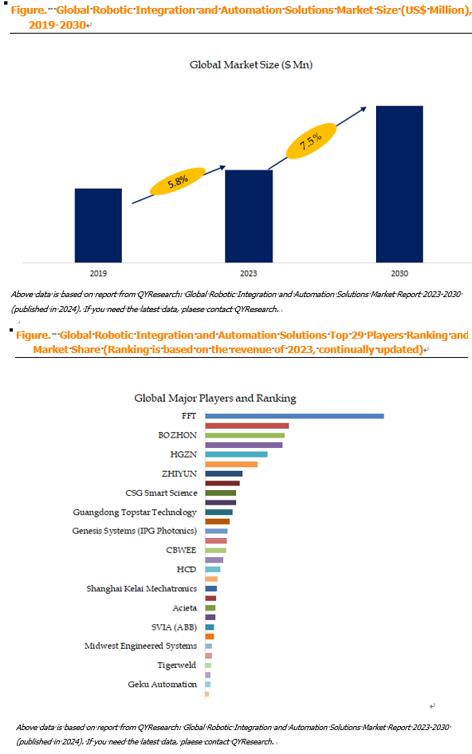

Robotic integration and automation solutions refer to the integration of robotic systems into industrial processes to automate tasks, improve efficiency, and enhance overall productivity. These solutions involve the use of robotics, sensors, software, and other technologies to create a seamless and integrated workflow. The goal is to streamline operations, reduce manual labor, and achieve higher levels of precision and consistency in manufacturing and other industries. Integration is the process of programming and outfitting industrial robots so they can perform automated manufacturing tasks. Robot integrators are companies that will analyse your robotic system needs, provide a plan for automation, and put the automation into production. Robot system integration is based on large-scale projects and factory production lines, and provides services such as system design and equipment integration in industrial control, transmission, communication, production and management based on the robot body. The core hardware and software are the robot body, robot end-effectors and fixtures, advanced manufacturing process equipment, various sensors (including tactile, force, vision, etc.), on-site industrial control software and information interaction, etc. According to the new market research report “Global Robotic Integration and Automation Solutions Market Report 2023-2030”, published by QYResearch, the global Robotic Integration and Automation Solutions market size is projected to reach USD 77.63 billion by 2030, at a CAGR of 7.5% during the forecast period. According to QYResearch Top Players Research Center, the global key manufacturers of Robotic Integration and Automation Solutions include FFT, Motoman Robotics, BOZHON, STEP, HGZN, Colibri Technologies, ZHIYUN, EFFORT, CSG Smart Science, Guangzhou Risong Technology, etc. In 2023, the global top 10 players had a share approximately 5.0% in terms of revenue. Market Drivers: D1: Efficiency Improvement: One of the primary drivers is the pursuit of increased efficiency in industrial processes. Robotic integration and automation solutions enable tasks to be performed with precision, speed, and consistency, leading to overall process optimization and reduced production times. D2: Technological Advancements: Continuous advancements in robotics, artificial intelligence, and sensor technologies drive innovation in automation solutions. Improved capabilities, increased functionality, and reduced costs of these technologies contribute to the growth of the market. D3: Rising Demand in Industries: Industries such as automotive, electronics, healthcare, and logistics are witnessing increased demand for automation to meet production volumes, handle intricate tasks, and adapt to changing market requirements. Restraint: R1: Complexity of Implementation: Integrating robotic systems into existing processes can be complex, requiring expertise in both automation technology and the specific industry. The need for specialized skills during the implementation phase can contribute to higher costs. R2: Customization Requirements: Industries often have unique processes and requirements. Customizing robotic integration solutions to meet specific needs adds to the complexity and cost of implementation. R3: Technology Upgrades: Rapid technological advancements may lead to the need for frequent upgrades to keep automation systems current and competitive. These upgrades can contribute to ongoing costs for businesses. Challenges: C1: Human-Robot Collaboration: Ensuring the safe interaction between humans and robots is crucial. Safety concerns, especially in environments where humans and robots work together, may slow down the adoption of automation solutions. Adhering to safety standards and implementing robust safety features is a priority. C2: Downtime Impact: Regular maintenance is crucial for the optimal performance of robotic systems. However, scheduled maintenance can result in downtime, affecting overall production efficiency. Finding a balance between maintenance needs and continuous operation is a challenge. C3: Supply Chain Challenges: The semiconductor and electronic components used in automation systems are subject to global supply chain disruptions. Shortages or delays in the availability of critical components can impact the deployment and maintenance of robotic integration solutions.  | |

| Target Nation: All Nations Target City : All Cities Last Update : 22 April 2024 3:52 AM Number of Views: 9 | Item Owner : Joyce Contact Email: Contact Phone: 13051817187 |

| Friendly reminder: Click here to read some tips. | |

UKAdsList > Internet Services > Other Internet Services > Item ID 8580840

© 2024 UKAdsList.com

USNetAds.com | GetJob.us | CANetAds.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2024-04-23 (0.331 sec)