Free Classifieds at UKAdsList.com - View Item Content by ID 8581630

UKAdsList > Internet Services > Other Internet Services > Item ID 8581630

Item ID 8581630 in Category: Internet Services - Other Internet Services

Cannot view this item. It could be pending, expired or deleted.

Below item is randomly selected from the same category and may have similar content.

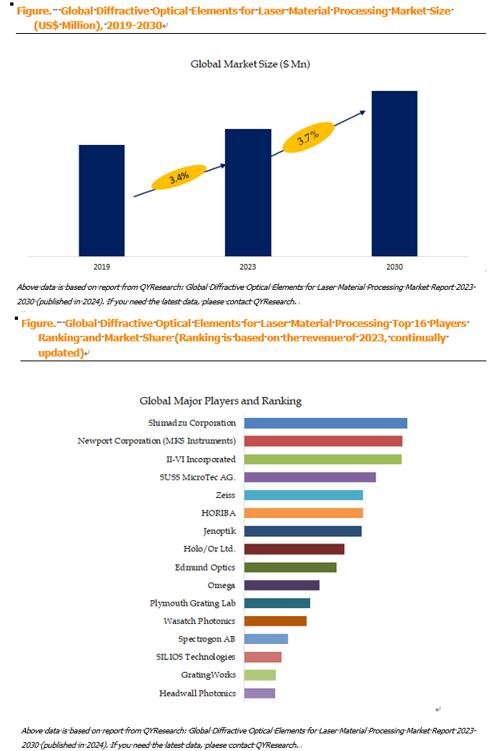

Diffractive Optical Elements for Laser Material Processing, Global Market Size Forecast, Top 16 Play | |

Diffractive Optical Elements (DOEs) are specialized optical components designed to manipulate light in ways that are not achievable with traditional optical elements like lenses and mirrors. In the context of laser material processing, DOEs are used to shape, split, or redistribute laser beams for specific applications. Here are some key aspects of DOEs in laser material processing: Beam Shaping: DOEs are often employed to reshape the intensity distribution of a laser beam. This can be useful in applications where a specific beam profile is required, such as achieving a uniform intensity over an area or generating a specific pattern. Beam Splitting: DOEs can be designed to split a single laser beam into multiple beams. This is useful in applications where simultaneous processing at different locations is required, or for creating arrays of beams for parallel processing. Focusing and Collimation: DOEs can be designed to manipulate the phase of the laser beam to achieve focusing or collimation. This is beneficial in laser material processing applications where precise control over the beam's characteristics is crucial. Aberration Correction: DOEs can help correct optical aberrations, improving the overall quality of the laser beam. This is important for applications that demand high precision and quality, such as laser micromachining or lithography. Wave front Modulation: DOEs can modulate the wavefront of a laser beam, allowing for the creation of complex light patterns. This is valuable in applications like laser engraving, where intricate designs or patterns need to be produced. Efficiency: Diffractive elements can be designed to be highly efficient, minimizing energy losses during the optical manipulation process. DOEs are preferred in certain laser material processing applications due to their ability to provide precise control over the laser beam characteristics. They are designed using computer-generated holography or other advanced techniques to achieve the desired optical effects. Their versatility makes them valuable tools in fields such as laser cutting, welding, marking, and additive manufacturing. According to the new market research report “Global Diffractive Optical Elements for Laser Material Processing Market Report 2023-2030”, published by QYResearch, the global Diffractive Optical Elements for Laser Material Processing market size is projected to reach USD 0.33 billion by 2030, at a CAGR of 3.7% during the forecast period. According to QYResearch Top Players Research Center, the global key manufacturers of Diffractive Optical Elements for Laser Material Processing include Shimadzu Corporation, Newport Corporation (MKS Instruments), II-VI Incorporated, SUSS MicroTec AG., Zeiss, HORIBA, Jenoptik, Holo/Or Ltd., Edmund Optics, Omega, etc. In 2023, the global top five players had a share approximately 19.0% in terms of revenue. Market Drivers: D1: Advanced Laser Processing Techniques: As laser material processing techniques continue to advance, the demand for sophisticated optical elements like DOEs increases. Applications such as laser ablation, engraving, and micro-machining benefit from the unique capabilities of DOEs, driving their adoption in cutting-edge technologies. D2: Customization and Flexibility: DOEs can be customized to meet specific requirements of different applications. This flexibility in design and functionality makes them suitable for a wide range of laser material processing tasks. Industries with diverse processing needs find DOEs adaptable to their specific requirements. D3: Increased Productivity: In manufacturing and material processing, efficiency and speed are crucial. DOEs enable the manipulation of laser beams to achieve optimized processing speeds and improved productivity. The ability to shape beams for specific applications helps in achieving faster and more efficient material removal or modification. For more information, please contact the following e-mail address: Email: global@qyresearch.com Website: https://www.qyresearch.com QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.  | |

| Target Nation: All Nations Target City : All Cities Last Update : 22 April 2024 3:54 AM Number of Views: 13 | Item Owner : Joyce Contact Email: Contact Phone: 13051817187 |

| Friendly reminder: Click here to read some tips. | |

UKAdsList > Internet Services > Other Internet Services > Item ID 8581630

© 2024 UKAdsList.com

USNetAds.com | GetJob.us | CANetAds.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2024-04-25 (0.365 sec)